Sheet Metal Welding Parts

Sheet metal welding is a fabrication process used to permanently join individual metal components into a complete, unified structure. By applying controlled heat and, when required, filler material, welding creates strong connections that allow separate sheet metal parts to function as a single assembly. At XTron Metal, this process is widely used to produce enclosures, frames, brackets, and structural components where strength and durability are essential.

Custom Sheet Metal Welding Service

Sheet metal welding is the stage where fabricated components are permanently joined and transformed into a functional assembly. After cutting and bending define the shape of individual parts, welding determines how those parts perform together as a structure. The effectiveness of this process directly influences load-bearing capacity, dimensional stability, and the overall service life of the finished product.

At XTron Metal, sheet metal welding is approached with an emphasis on control and consistency. By carefully managing joint design, material compatibility, and heat input, welded assemblies are able to maintain structural integrity and dimensional accuracy throughout fabrication. This considered approach ensures welded parts are well suited for surface finishing, assembly, and reliable operation in demanding industrial applications.

Types of Welding Methods at XTron

XTron Metal applies different welding methods based on material type, thickness, joint design, and application requirements. Selecting the appropriate welding process is essential to achieving joint strength, dimensional stability, and consistent quality in sheet metal assemblies. Our team evaluates each project to determine the most suitable welding approach for reliable results.

MIG Welding (Gas Metal Arc Welding)

MIG welding is commonly used for carbon steel and stainless steel sheet metal where efficiency and stable weld quality are required. This method provides good penetration and consistent weld appearance, making it suitable for frames, enclosures, and general structural assemblies.

TIG Welding (Gas Tungsten Arc Welding)

TIG welding offers precise control over heat input and weld formation, making it well suited for stainless steel, aluminum, and applications with higher appearance or dimensional requirements. This method is often used for thinner materials, visible welds, or components requiring clean, controlled joints.

Spot Welding

Spot welding is used for joining overlapping sheet metal parts, particularly in thin-gauge steel assemblies. By applying localized heat and pressure, this method creates strong joints efficiently and is commonly applied in enclosures, panels, and repetitive sheet metal assemblies.

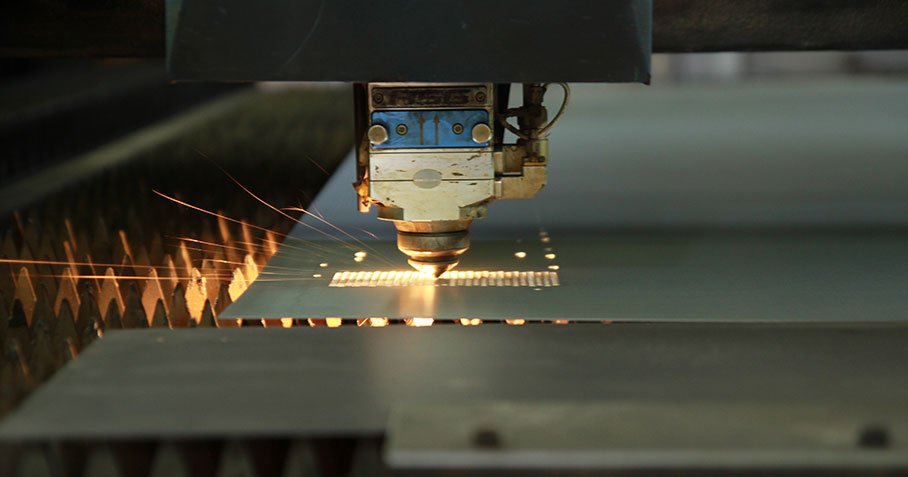

Laser Welding

Laser welding is used for applications that require high precision, low heat input, and minimal distortion. By using a focused laser beam, this method creates narrow, clean weld seams with excellent control over heat-affected areas. It is well suited for thin-gauge sheet metal, stainless steel components, and assemblies where dimensional accuracy and appearance are critical.

Sheet Metal Welding Materials

XTron Metal provides sheet metal welding services for a range of commonly used industrial materials. Material selection plays a critical role in weld quality, joint strength, heat control, and dimensional stability. Different metals respond differently to welding processes, and material thickness further influences heat input, distortion control, and overall assembly performance. For this reason, material compatibility is carefully evaluated before welding begins.

Our welding capabilities support carbon steel, stainless steel, aluminum, and galvanized sheet metal commonly used in fabricated enclosures, frames, brackets, and structural assemblies. Based on material type, thickness, and joint design, appropriate welding methods such as MIG welding, TIG welding, spot welding, or laser welding are selected to achieve stable weld formation and consistent results. This process-oriented approach allows welded sheet metal parts to meet functional, structural, and appearance requirements across a wide range of applications.

Common welding materials include:

Carbon Steel Plate (Q235 / A36 / Mild Steel)

SPCC Cold Rolled Steel

SUS Stainless Steel (201 / 304 / 316)

Aluminum Plate (5052 / 6061)

SECC Electrolytic Galvanized Steel

Material thickness and joint configuration are reviewed during the quotation and planning stage to ensure welding feasibility, controlled heat input, and reliable joint performance throughout production.

Why Choose XTron for Sheet Metal Welding?

Controlled Weld Stability

Sheet metal welding requires careful control to maintain part alignment and dimensional accuracy. At XTron Metal, welding is planned with consideration for joint configuration, heat distribution, and welding sequence to support consistent results. This process-oriented approach helps welded assemblies maintain structural integrity and dimensional stability throughout fabrication and downstream operations.

Multiple Welding Methods for Different Applications

XTron Metal supports multiple welding methods, including MIG welding, TIG welding, spot welding, and laser welding, allowing us to match the welding process to material type, thickness, joint design, and application requirements. This flexibility ensures appropriate heat input, stable weld quality, and reliable joint performance across a wide range of sheet metal assemblies.

Global Shipping Expertise

XTron Metal supports customers worldwide with reliable international shipping and export coordination. Our team is experienced in handling overseas orders, export packaging, and international logistics to ensure sheet metal welding parts are delivered safely and on schedule. No matter where you are located, we provide clear communication, proper documentation, and dependable shipment execution, making it easier to source precision sheet metal components through a reliable manufacturing partner.

Sheet Metal Welding Parts Applications

Sheet Metal Welding Service Related FAQs

How do you choose the appropriate welding method for my project?

The welding method is selected based on material type, thickness, joint design, and application requirements. Factors such as heat input, dimensional stability, and appearance expectations are evaluated during the planning stage. At XTron Metal, methods such as MIG welding, TIG welding, spot welding, or laser welding are chosen to achieve stable joints and consistent results for each specific application.

How do you minimize deformation in sheet metal welding?

Deformation in sheet metal welding is minimized through proper planning and controlled execution rather than relying on welding force alone. Key considerations include joint design, material thickness, and selecting a welding method that allows appropriate heat input for the application. Managing these factors helps reduce excessive thermal stress during welding.

At XTron Metal, deformation control is addressed by optimizing welding sequence, balancing heat distribution, and maintaining stable part positioning throughout the welding process. By carefully controlling heat input and assembly order, welded components are able to maintain dimensional accuracy and structural stability, making them suitable for downstream finishing, assembly, and demanding industrial applications.

How do you manage weld appearance and post-weld finishing requirements?

Weld appearance and post-weld finishing are considered during the welding planning stage rather than after welding is completed. Factors such as weld location, bead size, and joint design are selected to balance structural strength with surface requirements. This approach helps ensure welds are suitable for subsequent processes such as grinding, powder coating, or painting.

At XTron Metal, welding parameters are controlled to achieve consistent weld seams and minimize excessive spatter or uneven buildup. By managing these details during welding, assembled sheet metal parts can meet both functional requirements and appearance expectations after finishing, without unnecessary rework.

GET A FREE QUOTE TODAY

Your top-tier metal fabrication partner from China.