Sheet Metal Cabinets

Sheet metal cabinets provide enclosed, organized spaces to protect equipment, components, and systems. Designed to balance strength, accessibility, and environmental protection, cabinets play a critical role in both industrial and commercial settings. At XTron Metal, sheet metal cabinets are fabricated to support reliable installation, long-term use, and clean system integration.

Custom Sheet Metal Cabinets Service

Sheet metal cabinets are enclosure structures designed to house, protect, and organize internal components. Unlike open frames or chassis, cabinets must address multiple functional requirements at once, including structural rigidity, access control, airflow management, and surface durability. Their performance directly affects equipment protection, maintenance efficiency, and overall system reliability.

At XTron Metal, cabinet fabrication is approached as an enclosure solution rather than a collection of panels. Door design, panel alignment, mounting features, and joining methods are considered together to ensure the finished cabinet functions as a complete unit. This enclosure-focused approach allows cabinets to meet both mechanical and practical use requirements across a wide range of applications.

Common Applications of Sheet Metal Cabinets

Sheet metal cabinets are widely used across industrial, commercial, and infrastructure environments where equipment protection, organization, and controlled access are required. Their enclosed structure, configurable layout, and material versatility make them a reliable solution for housing sensitive components in both indoor and outdoor settings.

Industrial Equipment and Machinery Cabinets

In industrial manufacturing and processing environments, sheet metal cabinets are commonly used to house electrical systems, mechanical components, and machine controls. These cabinets provide physical protection against dust, impact, and operational wear while maintaining structural rigidity under continuous use. Properly fabricated industrial cabinets also support vibration resistance and long-term durability, which are critical for maintaining stable equipment operation.

Electrical and Control Cabinets

Sheet metal cabinets play a central role in electrical and control systems by organizing wiring, breakers, PLCs, and control modules within a secure enclosure. Accurate panel layout, mounting features, and door alignment are essential for safe installation and maintenance. Sheet metal control cabinets are widely applied in factories, power distribution systems, and building infrastructure where reliability and accessibility are key requirements.

Automation and Control System Enclosures

In automation and smart control applications, sheet metal cabinets are used to integrate controllers, power supplies, networking equipment, and communication components into a compact enclosure. Their modular design allows consistent layouts across different system configurations, supporting scalability and efficient deployment. Well-designed automation cabinets also facilitate cable management and airflow planning, contributing to system stability.

Commercial, Utility, and Infrastructure Cabinets

Sheet metal cabinets are also extensively used in commercial buildings, utilities, and public infrastructure projects. Typical applications include telecommunications cabinets, utility enclosures, and service access cabinets. In these environments, material selection and enclosure design are often tailored to provide corrosion resistance, security, and ease of access, ensuring reliable performance in varied operating conditions.

Sheet Metal Cabinets Materials

Material selection for sheet metal cabinets is driven by the operating environment, installation conditions, and expected service life. Cabinets are often specified based on corrosion resistance, surface finish requirements, weight considerations, and overall durability rather than purely structural strength. Selecting the appropriate material ensures the cabinet performs reliably while remaining practical to fabricate, finish, and install.

XTron Metal fabricates sheet metal cabinets using materials commonly specified for electrical, industrial, and utility enclosures. Material choice and thickness are reviewed in relation to cabinet size, usage environment, and finishing requirements to ensure consistent fit, protection, and long-term performance.

Common materials for sheet metal cabinets include:

Cold Rolled Steel (SPCC)

Good dimensional accuracy and surface flatness, suitable for cabinets requiring clean appearance and secondary surface finishing.Galvanized Steel (SGCC / SECC)

Zinc-coated for improved corrosion resistance, commonly used for cabinets exposed to humidity or industrial environments.Stainless Steel (201 / 304 / 316)

High corrosion resistance and durability, suitable for harsh, outdoor, or hygiene-sensitive applications.Aluminum Plate (5052 / 6061)

Lightweight and corrosion-resistant, suitable for cabinets where weight reduction or easier handling is required.

Final material selection is confirmed during the planning stage to align fabrication methods with functional and environmental requirements.

Why Choose XTron for Sheet Metal Cabinets?

Enclosure-Oriented System Design

A sheet metal cabinet must function as a complete enclosure rather than a collection of panels. At XTron Metal, cabinet fabrication is approached by considering door operation, panel interaction, internal layout, and mounting relationships together. This enclosure-oriented design thinking ensures cabinets maintain consistent fit, accessibility, and functional integrity once installed and in use.

Ready for Installation and Integration

Sheet metal cabinets are produced with installation and end use in mind. Mounting provisions, access openings, and structural features are coordinated to support efficient installation and integration into equipment or facilities.

Global Shipping Expertise

XTron Metal supports customers worldwide with reliable international shipping and export coordination. Our team is experienced in handling overseas orders, export packaging, and international logistics to ensure sheet metal cabinets are delivered safely and on schedule. No matter where you are located, we provide clear communication, proper documentation, and dependable shipment execution, making it easier to source precision sheet metal components through a reliable manufacturing partner.

Sheet Metal Cabinets Related FAQs

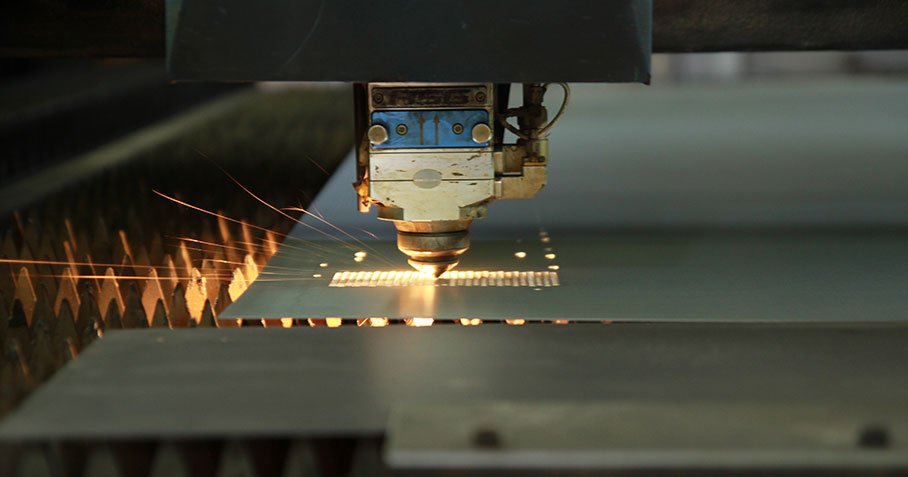

How does custom sheet metal cabinet fabrication work at XTron Metal?

Custom cabinet fabrication at XTron Metal begins with a review of your drawings, layout requirements, and functional needs such as access, mounting, and installation conditions. Cabinet structure, door configuration, and internal mounting logic are evaluated together to ensure the enclosure functions properly as a complete unit.

Fabrication is then planned as a coordinated process covering panel forming, joining, and assembly. This approach allows the finished cabinet to maintain consistent fit, reliable operation, and readiness for installation in its intended environment.

How does XTron’s sheet metal cabinets support installation and ongoing maintenance?

Our sheet metal cabinets are fabricated with installation and maintenance considerations in mind. Factors such as door configuration, panel alignment, and internal clearances are reviewed during fabrication to support efficient installation, inspection, and servicing. At XTron Metal, customer designs and requirements are carefully evaluated to ensure the finished cabinet balances enclosure protection with practical accessibility.

How do you ensure consistency across multiple sheet metal cabinet units?

Consistency across cabinet units is achieved by maintaining stable fabrication references throughout cutting, forming, and assembly. Critical features such as panel dimensions, mounting points, and door interfaces are controlled to ensure repeatable fit and alignment. At XTron Metal, this approach helps ensure each cabinet unit assembles and installs consistently across both small batches and production runs.

GET A FREE QUOTE TODAY

Your top-tier metal fabrication partner from China.