Sheet Metal Chassis Fabrication

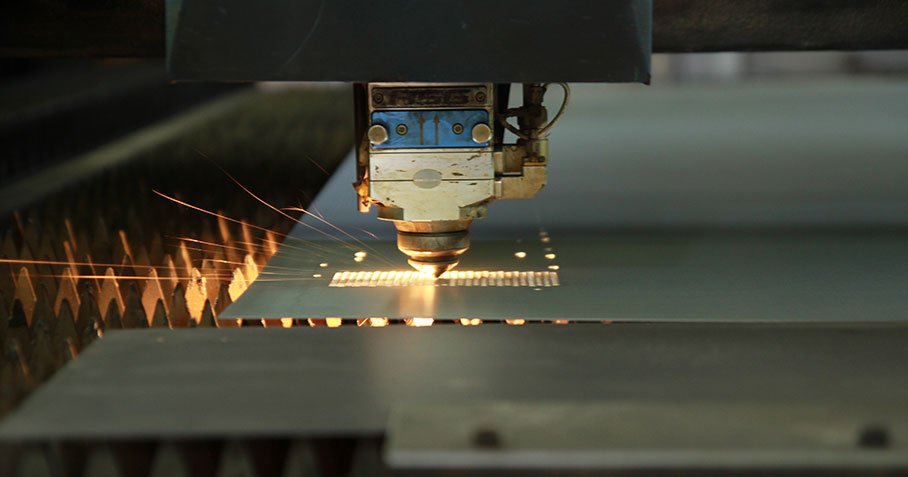

A sheet metal chassis forms the structural foundation of an assembly, supporting components, loads, and interfaces within a defined geometry. Through cutting, forming, and joining, sheet metal chassis provide strength, alignment, and dimensional control for complex systems. At XTron Metal, sheet metal chassis are manufactured to support reliable assembly and long-term structural performance.

Custom Sheet Metal Chassis Fabrication

A sheet metal chassis is not simply a collection of formed panels. It is the underlying structure that determines how components are positioned, supported, and retained throughout a product’s lifecycle. From initial assembly to long-term operation, the chassis governs alignment, stiffness, and overall system behavior.

What makes chassis fabrication challenging is the need to balance strength, accuracy, and manufacturability at the same time. Multiple bends, joints, and mounting interfaces must work together without introducing distortion or misalignment. At XTron Metal, chassis manufacturing is approached from a system perspective. Structural paths, interface locations, and fabrication sequence are considered together so the finished chassis performs consistently as an integrated whole.

Common Applications of Sheet Metal Chassis

Sheet metal chassis are widely used in products where components must be securely supported within a defined structural envelope.

Industrial Equipment Platforms

In industrial machinery and equipment, chassis assemblies act as load-bearing platforms that support motors, actuators, control systems, and mechanical subassemblies. A well-designed chassis helps manage vibration and maintains alignment under operating loads.

Electrical and Control Systems

For electrical cabinets and control systems, the chassis serves as the internal framework that organizes components and mounting points. Accurate chassis geometry supports proper clearances, cable routing, and repeatable installation across units.

Automation and Modular Systems

Automation equipment often relies on modular chassis designs to allow flexible configuration and expansion. Sheet metal chassis provide a balance of rigidity and adaptability, enabling standardized layouts while accommodating system variations.

Mechanical Substructures

In larger mechanical assemblies, sheet metal chassis are frequently used as internal frames or substructures. Their ability to combine structural function with fabrication efficiency makes them suitable for scalable and repeatable system designs.

Sheet Metal Chassis Materials

Material selection is fundamental to how a sheet metal chassis performs as a structural system. Unlike standalone parts, a chassis must maintain stiffness, alignment, and load-bearing capability across multiple interfaces while supporting mounted components over time. The chosen material directly influences structural strength, vibration behavior, corrosion resistance, weight, and long-term dimensional stability.

Carbon steel is commonly used for sheet metal chassis where strength, rigidity, and cost efficiency are priorities. Its predictable forming and welding characteristics make it well suited for load-bearing frames, industrial equipment bases, and machinery chassis. Cold rolled steel is often selected when tighter dimensional control and surface consistency are required, particularly for chassis designs with multiple mounting points or interface features.

Stainless steel chassis are used in environments where corrosion resistance, hygiene, or durability is critical. While offering higher strength and environmental resistance, stainless steel requires careful planning in forming and joining to maintain geometry across the assembly. Aluminum is chosen for chassis designs where weight reduction is a key requirement. Its lower density enables lighter structural systems, though thickness, reinforcement strategy, and joint design must be considered to achieve the required stiffness.

At XTron Metal, chassis materials are evaluated in relation to the full system rather than individual components. Factors such as load paths, component mounting locations, forming complexity, and welding sequence are considered alongside material properties. This material-centric approach ensures that each chassis is not only manufacturable, but structurally appropriate for its intended application and operating conditions.

Common materials for sheet metal chassis include:

Carbon Steel Plate (Q235 / A36 / Mild Steel)

SPCC Cold Rolled Steel

Stainless Steel (201 / 304 / 316)

Aluminum Plate (5052 / 6061)

SECC Electrolytic Galvanized Steel

Material thickness and structural role are reviewed during the planning stage to ensure the finished chassis meets performance, assembly, and durability expectations.

Why Choose XTron for Sheet Metal Chassis Fabrication?

Structural Thinking at the System Level

A sheet metal chassis must function as a unified structure rather than a collection of formed parts. At XTron Metal, chassis fabrication is approached from a system perspective, considering load paths, stiffness distribution, and interface relationships across the entire assembly. This structural thinking ensures the chassis supports components consistently and performs reliably under real operating conditions.

Geometry Stability Across the Structure

Chassis performance depends on how well geometry is maintained throughout forming and joining. XTron Metal focuses on preserving alignment and dimensional consistency across bends, joints, and mounting features so the final structure assembles as intended. This attention to geometry stability reduces fit-up issues and supports repeatable assembly in both prototype and production builds.

Global Shipping Expertise

XTron Metal supports customers worldwide with reliable international shipping and export coordination. Our team is experienced in handling overseas orders, export packaging, and international logistics to ensure sheet metal chassis are delivered safely and on schedule. No matter where you are located, we provide clear communication, proper documentation, and dependable shipment execution, making it easier to source precision sheet metal components through a reliable manufacturing partner.

Sheet Metal Chassis Fabrication Applications

Sheet Metal Chassis Fabrication Related FAQs

How does a sheet metal chassis support accurate component installation?

A well-fabricated chassis establishes reference geometry for mounting and alignment. Consistent dimensions across bends, holes, and welded features allow components to be installed without forcing or adjustment. XTron Metal emphasizes dimensional consistency throughout fabrication so chassis assemblies support repeatable, accurate component integration.

How does a sheet metal chassis support accurate component installation?

Custom sheet metal chassis fabrication at XTron Metal begins with a review of your drawings, specifications, and functional requirements. During this stage, factors such as material selection, structural layout, mounting interfaces, and assembly logic are evaluated to ensure the chassis can support components accurately and perform as intended within the system.

Once requirements are confirmed, fabrication is planned as a coordinated sequence that may include cutting, forming, welding, and assembly. Throughout this process, dimensional references and structural relationships are maintained so the finished chassis provides a stable foundation for component installation. This structured approach allows custom chassis designs to move efficiently from design intent to a manufacturable, assembly-ready structure.

How do sheet metal chassis support modular or scalable system designs?

Sheet metal chassis can be designed to accommodate different component layouts, sizes, or system configurations. By maintaining consistent reference geometry and mounting interfaces, a single chassis platform can support multiple variants. XTron Metal works from customer specifications to fabricate chassis structures that enable modularity while preserving structural integrity.

GET A FREE QUOTE TODAY

Your top-tier metal fabrication partner from China.