Sheet Metal Bending Parts

Sheet metal bending is a metal forming process that transforms flat metal sheets into functional, three-dimensional components through controlled deformation. By applying accurate force along defined bend lines, the process creates angles, flanges, and structural features essential for strength, fit, and assembly. At XTron Metal, our sheet metal bending services deliver consistent accuracy and fabrication-ready parts for both custom prototypes and production runs.

Custom Sheet Metal Bending Service

Sheet metal bending is the process of forming flat metal sheets into functional components by bending them at specified angles. Rather than removing material, the metal is shaped to create flanges, folds, and structural features that contribute to strength and dimensional stability. Components produced through sheet metal bending are widely used in applications such as electrical enclosures, equipment housings, support brackets, shelving systems, and structural frames across industrial and commercial environments.

At XTron Metal, sheet metal bending is performed as an integral stage of the fabrication process to ensure parts meet functional and assembly requirements. For example, flat steel sheets can be formed into control cabinets, aluminum panels can be bent into lightweight equipment enclosures, and stainless steel components can be shaped into durable brackets for industrial use. By carefully considering material properties, thickness, and bend geometry during planning, we deliver bending parts that are accurate, consistent, and ready for downstream welding, assembly, and surface finishing.

How Sheet Metal Bending Process Works at XTron

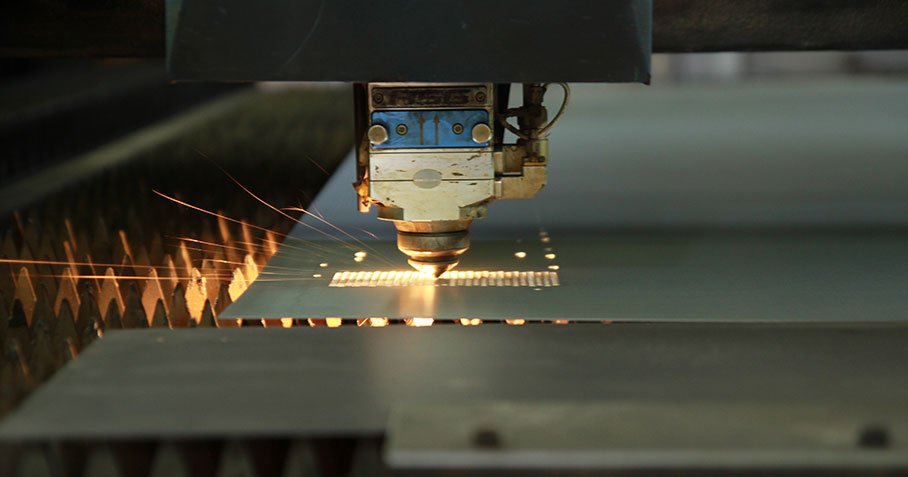

Sheet metal bending at XTron Metal is carried out using press brake equipment that applies controlled force to form metal sheets along predetermined bend lines. During the process, the sheet is positioned on a die, and a punch presses the material into the die opening to achieve the required bend angle and shape. The bend angle is determined by factors such as punch and die geometry, applied force, material thickness, and material mechanical properties.

To ensure bending accuracy and consistency, key parameters such as bend radius, bend allowance, and material springback are considered before forming begins. Different materials respond differently to bending, and adjustments are made to account for elastic recovery after forming. By controlling these variables, we are able to produce bends with stable angles, consistent dimensions, and repeatable results. This process allows laser cut sheets to be accurately formed into fabrication ready components suitable for assembly, welding, and surface finishing.

Sheet Metal Laser Cutting Materials & Thickness

In sheet metal bending, the compatibility between material selection and thickness plays a critical role in forming quality and production consistency. Different materials respond differently during the bending process, and unsuitable thickness choices can affect dimensional accuracy and process stability. At XTron Metal, material specifications and thickness ranges are reviewed at the planning stage to confirm bending feasibility and ensure stable, predictable results throughout production.

| Material | Key Characteristics | Typical Applications | Typical Bending Thickness Range |

|---|---|---|---|

| Carbon Steel Plate (Q235 / A36 / Mild Steel) | Good strength and formability with predictable bending behavior. | Structural frames, brackets, formed panels | 1.0 – 12.0 mm (≈ 0.04″ – 0.47″) |

| SPCC Cold Rolled Steel | Excellent surface finish and formability for precision bending. | Enclosures, brackets, formed sheet metal parts | 0.8 – 6.0 mm (≈ 0.03″ – 0.24″) |

| SUS Stainless Steel (201 / 304 / 316) | Higher strength with greater springback requiring controlled bending. | Panels, brackets, formed structural components | 0.5 – 6.0 mm (≈ 0.02″ – 0.24″) |

| Aluminum Plate (5052 / 6061) | Lightweight material with good formability depending on alloy. | Enclosures, panels, formed aluminum parts | 0.5 – 5.0 mm (≈ 0.02″ – 0.20″) |

| SECC Electrolytic Galvanized Steel | Good flatness and coating consistency for formed enclosures. | Electrical cabinets, control boxes | 0.6 – 3.0 mm (≈ 0.02″ – 0.12″) |

| Red Copper (Pure Copper) | High ductility and excellent bendability at thin gauges. | Electrical and conductive components | 0.5 – 3.0 mm (≈ 0.02″ – 0.12″) |

Thickness ranges shown are typical for sheet metal bending and may vary depending on bend radius, part geometry, and material grade.

Why Choose XTron for Sheet Metal Bending?

Advanced Bending Machinary

XTron Metal operates professional sheet metal bending machines designed to deliver stable forming force and consistent bend accuracy. Our press brake setup allows precise control of bend angles and repeatability across different materials and thicknesses, supporting both simple and complex bending requirements. This equipment foundation ensures reliable results for functional and structural bending parts.

Integration with Fabrication and Assembly Needs

Sheet metal bending services at XTron Metal are aligned with downstream fabrication processes such as welding, assembly, and surface finishing. By ensuring bends are accurate and dimensions are controlled, we deliver fabrication-ready parts that fit smoothly into the next production stage. This integration helps customers streamline manufacturing workflows and maintain stable quality across projects.

Global Shipping Expertise

XTron Metal supports customers worldwide with reliable international shipping and export coordination. Our team is experienced in handling overseas orders, export packaging, and international logistics to ensure sheet metal bending parts are delivered safely and on schedule. No matter where you are located, we provide clear communication, proper documentation, and dependable shipment execution, making it easier to source precision sheet metal components through a reliable manufacturing partner.

Sheet Metal Bending Parts Applications

Sheet Metal Bending Service Related FAQs

How does customization work for sheet metal bending?

Customization at XTron Metal begins with your drawings and quantity requirements. By reviewing CAD or PDF files together with order volume, our team evaluates material selection, thickness, bend geometry, and tolerance requirements to confirm bending feasibility. This early review helps ensure that part design, material behavior, and forming requirements are properly aligned before production begins.

Once specifications are confirmed, sheet metal bending is carried out according to the approved parameters, with attention to bend angles, radii, and material springback. This structured workflow supports both prototype development and repeat production, allowing custom bending parts to be produced efficiently while maintaining consistent quality and reliable lead times.

How do I choose the right material and thickness for sheet metal bending?

Selecting the appropriate material and thickness for sheet metal bending starts with understanding the application and performance requirements of the part. Structural components typically require materials such as carbon steel for strength and rigidity, while aluminum is often chosen for lightweight assemblies. Material properties including yield strength and hardness influence bendability and springback behavior, and thickness directly affects the required forming force and minimum bend radius. Cost, availability, and surface appearance may also factor into the selection process, depending on functional and aesthetic requirements.

At XTron Metal, our engineers will review your drawings and specifications during the quotation stage to evaluate material and thickness suitability for bending. By considering part geometry, bending method, and production requirements, we provide professional recommendations that help ensure reliable forming performance, manufacturability, and consistent results throughout production.

Myth vs Reality: Sheet Metal Bending

Myth: Sheet metal bending is a simple process that only depends on machine force.

Reality: While press brake force is important, bending accuracy depends on multiple factors, including material properties, thickness, bend radius, tooling selection, and springback behavior. Without proper process planning, even powerful equipment cannot guarantee consistent results.

Myth: If a part is bent to the correct angle during forming, it will retain that angle.

Reality: Most metals experience springback after bending, causing the angle to open slightly once the forming force is released. Controlling this effect requires experience with material behavior and appropriate compensation during bending.

Myth: Any sheet metal can be bent the same way as long as thickness is similar.

Reality: Different materials respond very differently during bending. Stainless steel, aluminum, and carbon steel each require specific considerations for bend radius, force, and angle correction. Successful bending relies on understanding these differences and adjusting the process accordingly.

At XTron Metal, sheet metal bending is managed as a controlled forming process rather than a single operation. By combining equipment capability with process knowledge, we deliver stable, repeatable bending results across a wide range of materials and part designs.

GET A FREE QUOTE TODAY

Your top-tier metal fabrication partner from China.