Laser Cutting Parts

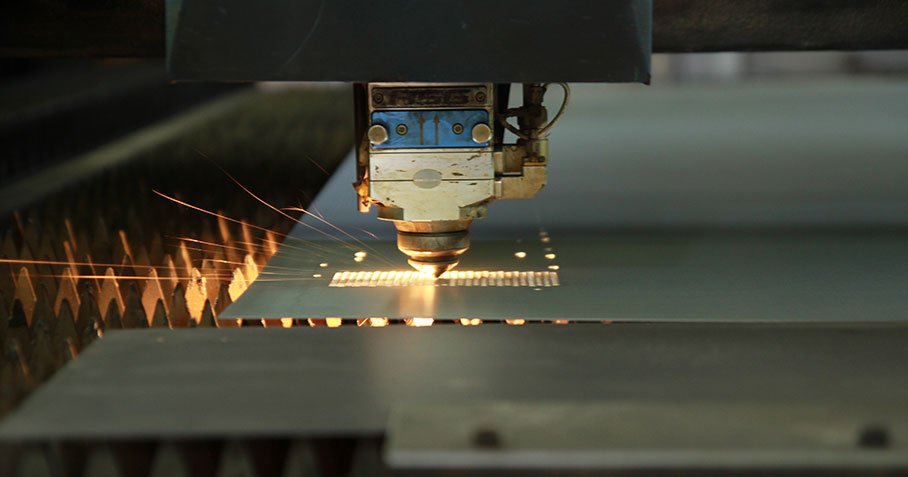

Laser sheet metal cutting uses a focused, high-energy laser beam to precisely cut metal plates according to CAD specifications. At XTron Metal, we handle thin plates under 3 mm and thick carbon steel plates up to 20 mm, delivering consistent accuracy, controlled cut quality, and reliable performance for a wide range of applications.

Custom Laser Cutting Service

Laser cutting is a precision manufacturing process that shapes many of the metal components we encounter in everyday life even often without being noticed. The brushed stainless steel panels of elevators, electrical cabinets in office buildings, automotive brackets hidden beneath vehicle frames, and the perforated metal panels used in building façades are all commonly produced through laser cutting. The process uses a high-energy laser beam, guided by programmed cutting paths, to cut metal sheets with a narrow kerf, high dimensional accuracy, and clean edges.

At XTron Metal, we provide custom laser cutting services for stainless steel and other sheet metals, focusing on stable cut quality, controlled tolerances, and repeatable results across production batches. Our laser cutting process delivers narrow kerf widths, minimal heat-affected zones, and consistent edge geometry, which helps maintain dimensional accuracy and flatness of parts. This level of control is critical for downstream processes such as press braking, welding, and surface finishing, as it reduces fit-up issues, minimizes post-processing, and ensures reliable assembly performance in both functional and appearance-critical applications.

Sheet Metal Laser Cutting Materials & Thickness

XTron Metal offers professional sheet metal laser cutting services for a wide range of industrially proven materials, including carbon steel, stainless steel, aluminum, galvanized steel, and copper. Our laser cutting capabilities support both structural and appearance-critical applications, delivering clean cut edges, controlled tolerances, and reliable repeatability across different material types. By precisely matching laser cutting parameters to each metal’s mechanical and surface characteristics, we help customers achieve accurate parts, efficient downstream fabrication, and consistent quality—making laser cutting an ideal solution for custom metal components, prototypes, and production runs.

| Material | Key Characteristics | Typical Applications | Typical Laser Cutting Thickness Range |

|---|---|---|---|

| Carbon Steel Plate (Q235 / A36 / Mild Steel) | Low-carbon structural steel with good strength, weldability, and cutting stability; widely used for laser cutting of thick plates and load-bearing components. | Structural frames, base plates, brackets, machine parts | 1.0 – 20.0 mm (≈ 0.04″ – 0.79″) |

| SPCC Cold Rolled Steel | Cold-rolled carbon steel with smooth surface finish and tight dimensional control; ideal for precision laser cutting and downstream bending and welding. | Brackets, frames, enclosures, general sheet metal fabrication | 0.8 – 12.0 mm (≈ 0.03″ – 0.47″) |

| SUS Stainless Steel (201 / 304 / 316) | Corrosion-resistant stainless steel with clean cut edges and excellent durability across multiple grades; suitable for both functional and appearance-critical parts. | Panels, brackets, frames, architectural and industrial components | 0.5 – 10.0 mm (≈ 0.02″ – 0.39″) |

| Aluminum Plate (5052 / 6061) | Lightweight aluminum alloy with good corrosion resistance and formability; supports complex geometries and precision laser cutting. | Enclosures, panels, mechanical and structural components | 0.5 – 8.0 mm (≈ 0.02″ – 0.31″) |

| SECC Electrolytic Galvanized Steel | Electro-galvanized steel with uniform zinc coating, high flatness, and smooth surface; well suited for laser cutting and secondary surface treatment. | Electrical enclosures, control boxes, precision sheet metal parts | 0.6 – 3.0 mm (≈ 0.02″ – 0.12″) |

| Red Copper (Pure Copper) | High-conductivity copper with excellent electrical and thermal performance; requires controlled laser parameters due to high reflectivity. | Electrical components, conductive parts, heat dissipation elements | 0.5 – 3.0 mm (≈ 0.02″ – 0.12″) |

Thickness ranges are shown in millimeters (mm) with approximate inch (″) equivalents. Actual laser cutting capability may vary depending on material grade, part geometry, tolerance requirements, and edge quality specifications.

Why Choose XTron for Sheet Metal Laser Cutting?

Process-Controlled Quality

XTron Metal applies a process-controlled approach to sheet metal laser cutting to ensure parts are suitable for downstream fabrication. By managing cut-edge quality, dimensional consistency, and flatness during the laser cutting stage, we help customers achieve reliable results in subsequent bending, welding, and surface finishing operations. This technical focus reduces fit-up issues, minimizes rework, and ensures consistent performance across both prototype builds and production runs.

Fast Turnaround Support

XTron Metal is structured to support quick turnaround times for laser-cut sheet metal parts, especially during the prototyping stage. By working directly from customer drawings and minimizing tooling requirements, laser cutting allows us to produce prototype parts efficiently for design validation and fit testing. This enables customers to move from concept to physical samples quickly and accelerate product development timelines.

Global Shipping Expertise

XTron Metal supports customers worldwide with reliable international shipping and export coordination. Our team is experienced in handling overseas orders, export packaging, and international logistics to ensure laser cut sheet metal parts are delivered safely and on schedule. No matter where you are located, we provide clear communication, proper documentation, and dependable shipment execution, making it easy to source precision sheet metal components from a single trusted supplier.

Sheet Metal Cutting Service Related FAQs

How does customization work for sheet metal laser cutting?

Customization at XTron Metal starts with your drawings and quantity requirements. By reviewing your CAD or PDF files and order volume, our team can quickly confirm material selection, thickness, tolerances, and cutting feasibility. Once these details are aligned, laser cutting allows us to proceed directly into production without tooling delays, delivering accurate, clean-cut parts with reliable lead times. This efficient workflow supports both rapid prototyping and repeat production, helping customers move smoothly from design to finished components.

Does laser cutting affect material strength or performance?

When properly controlled, laser cutting has minimal impact on material strength and performance. At XTron Metal, we manage cutting parameters according to material type and thickness to keep the heat-affected zone localized and controlled. This approach helps preserve the mechanical properties of the surrounding material, allowing laser-cut parts to be confidently used in structural, mechanical, and welded assemblies. By focusing on process stability and cut quality, XTron Metal delivers laser-cut components that perform reliably in real-world fabrication and assembly applications.

What makes laser cutting different from other metal cutting methods?

Laser cutting uses a focused, high-energy laser beam to cut metal with high precision and minimal material distortion. Compared to mechanical cutting or plasma cutting, laser cutting produces narrower kerf widths, cleaner edges, and better dimensional accuracy. This makes it especially suitable for parts that require tight tolerances, complex shapes, and clean edges for downstream fabrication.

GET A FREE QUOTE TODAY

Your top-tier metal fabrication partner from China.